| | Home | Board | Calendar | Education Tidbits | | Members | Newletters | Programs | Philanthropy | Slide Shows | Sign In | |

January 2026

A DISCUSSION OF THREAD AND SEWING MACHINE NEEDLES

Toot toot, Happy New Year! Wow, I never ever thought about getting to see the year 2026, it always seemed so far away. January contains the birthdays of some famous men, Martin Luther King and Benjamin Franklin. This month I am especially looking forward to attending the Road to California Quilt Show.

As I have told you before, I don't do new year's resolutions, but this year I decided to resolve to move forward into the future with gratitude for each day, looking forward to each and every new morning. I hope you will too.

This tidbit will introduce you to a discussion of thread and sewing machine needles. Thank you to Renee Jeske for giving me this challenge, I have enjoyed finding out lots of neat stuff. Renee asked for the following: discussion of different types of threads and their uses. Also discuss needles for your sewing machine. What do the different numbers mean? How often do I change my needle on my sewing machine? So, here goes, let's begin with thread.

Thread. I have included a discussion of thread construction methods below, taken directly from Superior Threads as provided by Lindas.com:

(begin quote)

Thread Construction Methods

Threads are either made of a natural fiber (cotton, wool, silk, linen) or synthetic fibers (rayon, polyester, nylon). While there are dozens of fiber types that could be twisted and spun into thread, there are a handful of common fibers that are used in sewing, quilting, serging, and embroidery.

- Spun thread - Cotton or polyester staple fibers are spun into single yarns and then twisted together.

- Corespun thread - Spun cotton or polyester staple fibers are wrapped around filament polyester fibers.

- Textured thread - Polyester or nylon that has been mechanically textured to make the thread fuzzy and stretchy and woollie-like. Texturing is a procedure used to increase the volume andthe elasticity of a filament yarn. The essential properties of textured yarns and the products made from hem are softness, fullness, a high degree of elasticity, thermal insulation and moisture-transporting properties.

- Filament thread - Shiny thread made of strands of polyester, rayon, or nylon.

- Monofilament thread - A single nylon or polyester filament. Polyester is highly preferred.

- Bonded thread - A strength-enhancing resin is coated on the outside of the thread. This increases the tensile strength and helps reduce friction. Bonded threads are usually meant for upholstery and heavy duty sewing applications. (end quote)

(begin quote)

Understanding Thread Weight

The weight or size of thread is an important consideration for any sewing project. Making proper adjustments relative to different thread weights will make sewing, quilting, or embroidery projects more enjoyable. The five most common methods of measurement of threads are weight, denier, tex, number, and composition standards.

Weight

A smaller weight number indicates a heavier thread. The weight of a thread is actually a length measurement. Dividing the length of thread by a set weight derives the exact measurement of a thread weight. A thread is labeled 40 wt. when 40 kilometers of that thread weighs 1 kilogram. A 30 wt. thread is heavier because it takes only 30 kilometers of thread to weigh one kilogram.

Denier

Weight in grams of 9000 meters of thread. If 9,000 meters weighs 120 grams, it is a 120-denier thread. Many polyester and rayon embroidery threads are 120/2, which equals 2 strands of 120-denier thread for a 240 denier total. Larger denier numbers are heavier threads.

Tex

Weight in grams of 1000 meters of thread. If 1,000 meters weighs 25 grams, it is a tex 25.

Larger tex numbers are heavier threads. (end quote)

Okay, that is a bunch of really good information. What you probably want to know is what weight to use for piecing my quilt blocks and quilt top? I recommend using a 50 weight thread for piecing blocks and quilt tops. I have seen recommendations on line to use from 50 to 80 weight.

Purchasing thread in large cone sizes generally gives you more thread for the money. Watch for sales and you can spend even less. Use a neutral color for your piecing and you only have to buy one color for sewing most everything. I use a natural or beige for most of my piecing. Alternatively, you could choose a pale gray as your neutral thread. If I am sewing black fabric, I use black thread. For those quilt tops with lots of white, I use all white thread for the piecing. The color choice is a personal preference.

Remember, the higher the number of the thread weight, the finer the thread, resulting in less bulk going into your 1/4-inch seam. The lower the number of the thread weight, results in thicker thread. You may want thicker thread to show off the final quilting design or to artfully show off hand work designs. To choose the proper weight of quilting thread, pay attention to the recommendations in your sewing machine manual or ask your long arm quilter.

Make sure to buy quality thread to ensure it will hold up for the life of your quilt. Keep thread stored upright in drawers or racks out of direct sunlight. If you don't know the age of a spool of thread, or where you got it, you probably should not use it in your quilt. Double check it to see if it breaks easily or if the thread comes off the spool with knots tied in it, if so, that thread is not a good choice to use in your quilt. Thread sizes and their recommended uses are included in a chart later in this tidbit.

If you sew with cotton fabric, use cotton thread. You can use polyester thread if you prefer. When the quilt is washed the cotton thread and the cotton fabric generally shrink together and the quilt remains fairly smooth. When a cotton quilt sewn with polyester thread is washed, the cotton shrinks, the poly-ester thread does not, the quilt and seams can pucker. Some folks love that pucker, others do not.

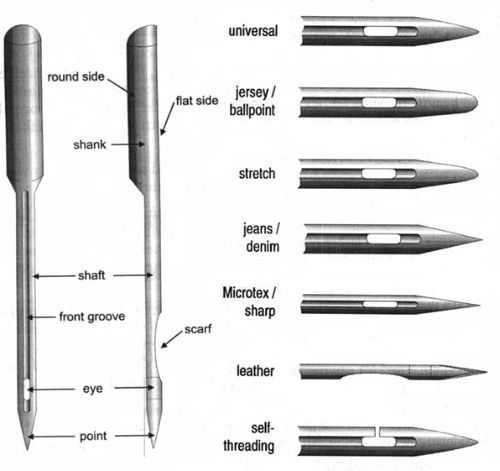

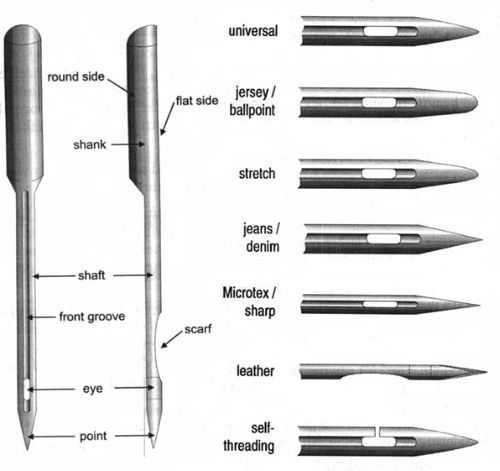

Sewing Machine Needles. The following shows all the parts of a sewing machine needle by needle type: (source: pinterest.com)

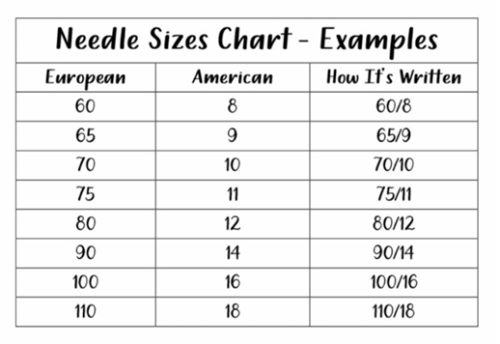

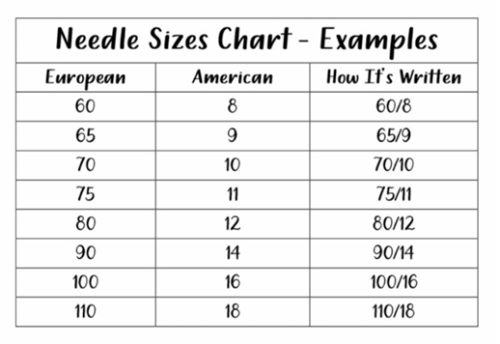

The next chart shows that the European size and the American size are not the same number, but they are typically combined on your needle package. (source: SEWINGMACHINEFUN.COM)

When you hear someone speak of needle size, it is stated as 12 or 14 and so on. The needle package may show it as 80/12 and 90/14, featuring the European size first, then the American.

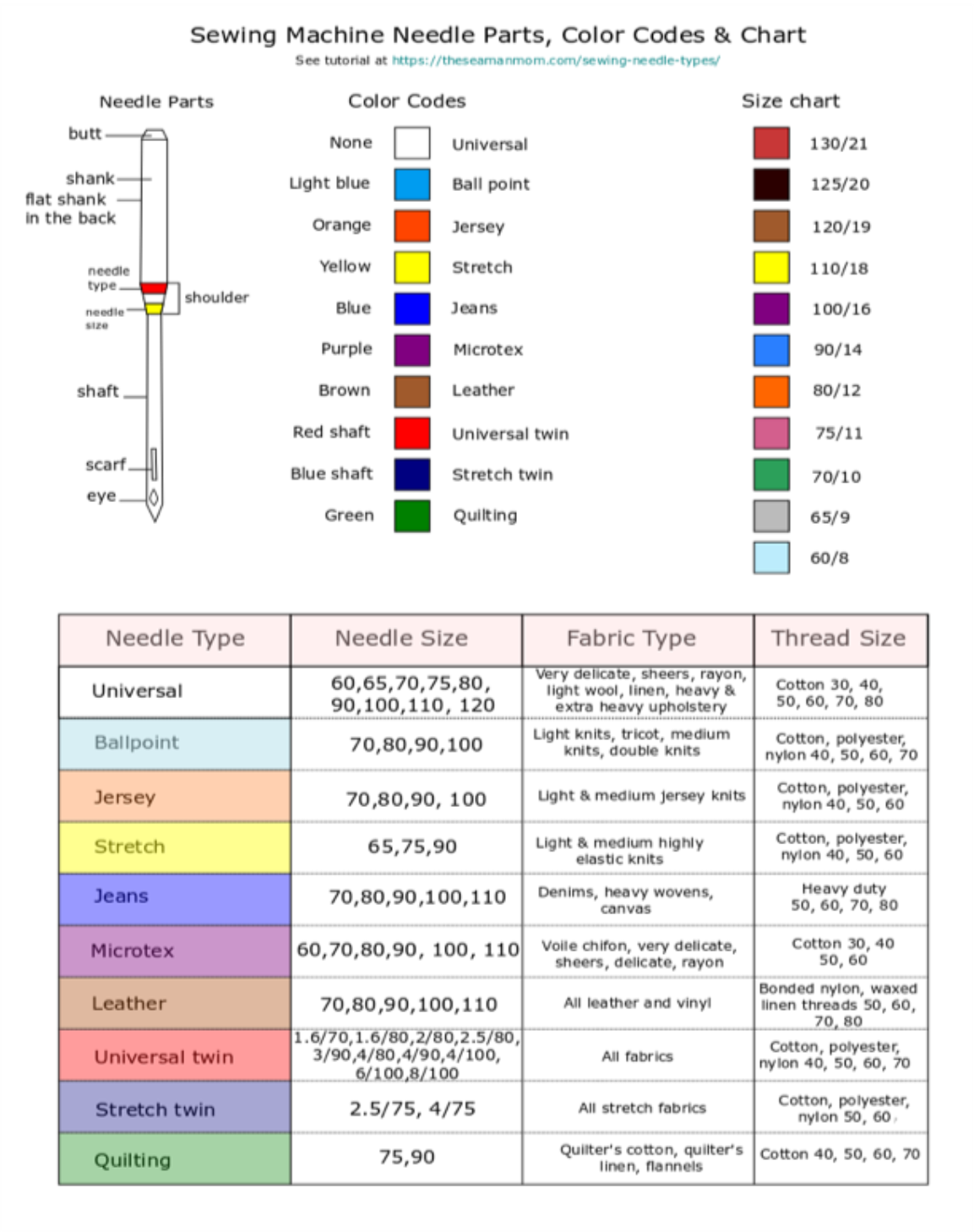

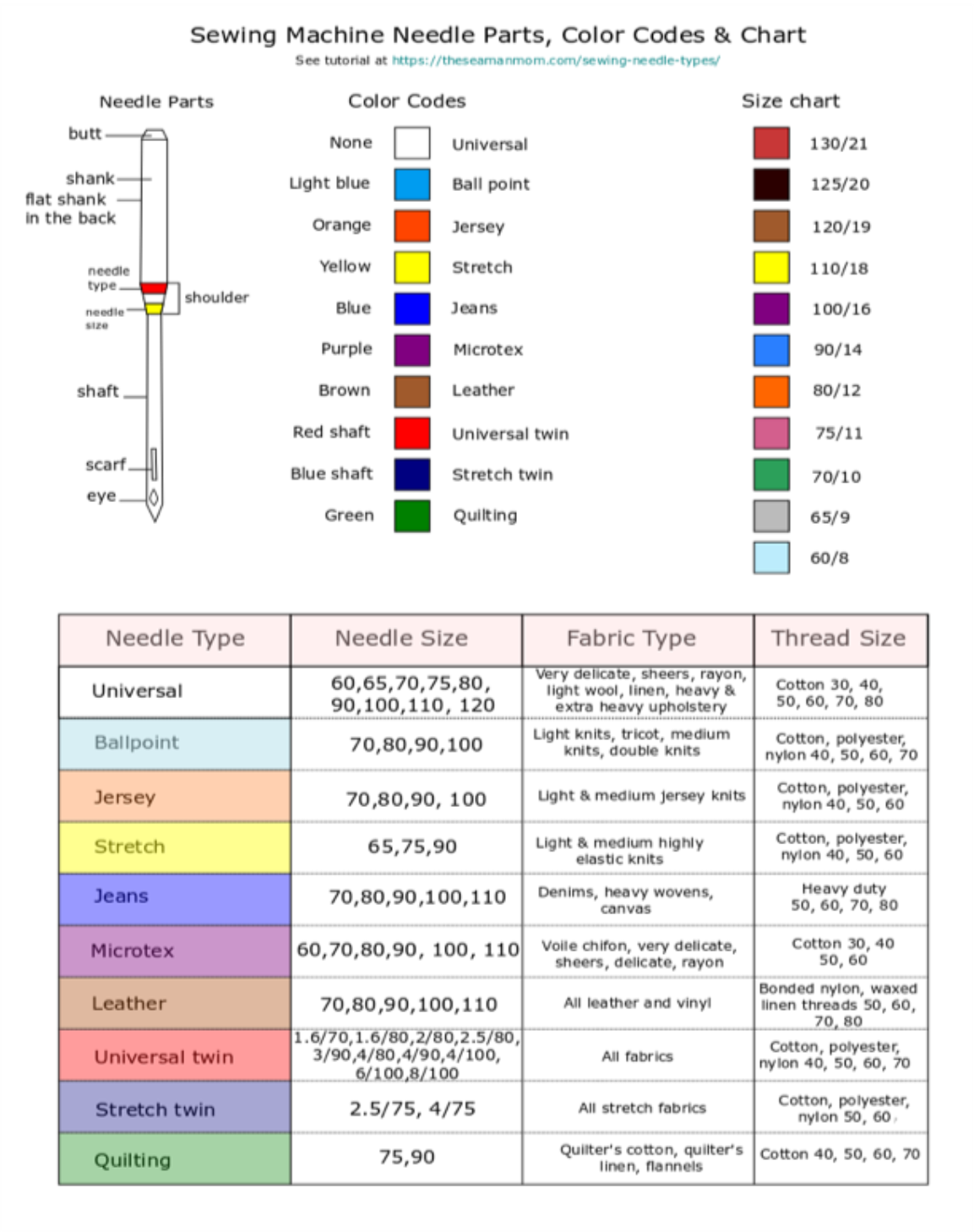

Matching the Thread Weight to the Sewing Machine Needle. The following chart shows you what type of needle and size of needle you need for specific types of fabric, and what size thread goes with the size of needle. The needle eye must be large enough to accommodate the size of the thread in a way that allows the thread to slide easily through the eye with the least amount of friction and no tangling.

When to Change Your Sewing Machine Needle.

Beginning in 2012, I began making quilts. Before quilting, I sewed garments, bags, toys, and did furniture and car upholstery. I learned how to make quilts and when to change needles from fellow quilters, experience, and doing research. These taught me to change my piecing needle each time I begin a new quilt project to ensure the needle was sharp enough to make my quilt top. Otherwise, if you have not sewed in a while and you cannot remember when you changed the needle, change the needle now. Currently, I have a small white board next to my sewing machine and I make a note when I last changed my needle and I note the size of the installed needle with a date. This simple step has saved me money by not changing a still sharp needle too soon.

If you notice your thread breaking, the needle makes a popping noise when piercing the fabric, or you have problems with your seam stitching, it is time to change your needle and to rethread the sewing machine. Before sewing on your project, test out the needle and thread with a scrap of fabric. If all is well, continue sewing your project.

I have also learned the hard way that I should remove my straight pins from my fabric before I run over them with the needle and thread. Running over a pin and having the needle hit the pin can break the sewing machine needle and/or the thread. The broken needle parts can ruin your fabric, hurt you, and possibly damage your sewing machine. It is recommended to change your needle if it hits a pin. The needle is most likely bent and will cause you problems sewing.

When you move from piecing to quilting, you will need to change from the size 12 piecing needle to a stronger needle to get through all the layers of the quilt sandwich. I recommend a size 14 for quilting or a larger size 16 if you are quilting through heavy thick layers or if your quilt top seams are especially bulky.

Some sewing machines sew at very high speeds like the Juki. The speed and friction causes the sewing machine needle shaft to become heated. If you sew at high speeds, you need a needle rated for high speed sewing. The heating caused by the high speed can weaken the shaft of the needle and can cause the needle to bend and break when it gets overly hot. If you are going to sew at high speeds, change to the appropriately rated needle.

That is it for this tidbit. I hope you enjoyed this journey with me. I learned a lot doing the research on this topic. Thank you again to Renee for this challenge. If you have an idea for a future tidbit, please let me know and I will be happy to research it and write it up. Blessings to you and your family. I plan to be back in February with another Educational tidbit. TTFN (tata for now).

Please e-mail the Webmaster for any problems with the website or any questions: webmaster@crazyquiltersguild.org

|

January 2026

A DISCUSSION OF THREAD AND SEWING MACHINE NEEDLES

Toot toot, Happy New Year! Wow, I never ever thought about getting to see the year 2026, it always seemed so far away. January contains the birthdays of some famous men, Martin Luther King and Benjamin Franklin. This month I am especially looking forward to attending the Road to California Quilt Show.

As I have told you before, I don't do new year's resolutions, but this year I decided to resolve to move forward into the future with gratitude for each day, looking forward to each and every new morning. I hope you will too.

This tidbit will introduce you to a discussion of thread and sewing machine needles. Thank you to Renee Jeske for giving me this challenge, I have enjoyed finding out lots of neat stuff. Renee asked for the following: discussion of different types of threads and their uses. Also discuss needles for your sewing machine. What do the different numbers mean? How often do I change my needle on my sewing machine? So, here goes, let's begin with thread.

Thread. I have included a discussion of thread construction methods below, taken directly from Superior Threads as provided by Lindas.com:

(begin quote)

Thread Construction Methods

Threads are either made of a natural fiber (cotton, wool, silk, linen) or synthetic fibers (rayon, polyester, nylon). While there are dozens of fiber types that could be twisted and spun into thread, there are a handful of common fibers that are used in sewing, quilting, serging, and embroidery.

- Spun thread - Cotton or polyester staple fibers are spun into single yarns and then twisted together.

- Corespun thread - Spun cotton or polyester staple fibers are wrapped around filament polyester fibers.

- Textured thread - Polyester or nylon that has been mechanically textured to make the thread fuzzy and stretchy and woollie-like. Texturing is a procedure used to increase the volume andthe elasticity of a filament yarn. The essential properties of textured yarns and the products made from hem are softness, fullness, a high degree of elasticity, thermal insulation and moisture-transporting properties.

- Filament thread - Shiny thread made of strands of polyester, rayon, or nylon.

- Monofilament thread - A single nylon or polyester filament. Polyester is highly preferred.

- Bonded thread - A strength-enhancing resin is coated on the outside of the thread. This increases the tensile strength and helps reduce friction. Bonded threads are usually meant for upholstery and heavy duty sewing applications. (end quote)

(begin quote)

Understanding Thread Weight

The weight or size of thread is an important consideration for any sewing project. Making proper adjustments relative to different thread weights will make sewing, quilting, or embroidery projects more enjoyable. The five most common methods of measurement of threads are weight, denier, tex, number, and composition standards.

Weight

A smaller weight number indicates a heavier thread. The weight of a thread is actually a length measurement. Dividing the length of thread by a set weight derives the exact measurement of a thread weight. A thread is labeled 40 wt. when 40 kilometers of that thread weighs 1 kilogram. A 30 wt. thread is heavier because it takes only 30 kilometers of thread to weigh one kilogram.

Denier

Weight in grams of 9000 meters of thread. If 9,000 meters weighs 120 grams, it is a 120-denier thread. Many polyester and rayon embroidery threads are 120/2, which equals 2 strands of 120-denier thread for a 240 denier total. Larger denier numbers are heavier threads.

Tex

Weight in grams of 1000 meters of thread. If 1,000 meters weighs 25 grams, it is a tex 25.

Larger tex numbers are heavier threads. (end quote)

Okay, that is a bunch of really good information. What you probably want to know is what weight to use for piecing my quilt blocks and quilt top? I recommend using a 50 weight thread for piecing blocks and quilt tops. I have seen recommendations on line to use from 50 to 80 weight.

Purchasing thread in large cone sizes generally gives you more thread for the money. Watch for sales and you can spend even less. Use a neutral color for your piecing and you only have to buy one color for sewing most everything. I use a natural or beige for most of my piecing. Alternatively, you could choose a pale gray as your neutral thread. If I am sewing black fabric, I use black thread. For those quilt tops with lots of white, I use all white thread for the piecing. The color choice is a personal preference.

Remember, the higher the number of the thread weight, the finer the thread, resulting in less bulk going into your 1/4-inch seam. The lower the number of the thread weight, results in thicker thread. You may want thicker thread to show off the final quilting design or to artfully show off hand work designs. To choose the proper weight of quilting thread, pay attention to the recommendations in your sewing machine manual or ask your long arm quilter.

Make sure to buy quality thread to ensure it will hold up for the life of your quilt. Keep thread stored upright in drawers or racks out of direct sunlight. If you don't know the age of a spool of thread, or where you got it, you probably should not use it in your quilt. Double check it to see if it breaks easily or if the thread comes off the spool with knots tied in it, if so, that thread is not a good choice to use in your quilt. Thread sizes and their recommended uses are included in a chart later in this tidbit.

If you sew with cotton fabric, use cotton thread. You can use polyester thread if you prefer. When the quilt is washed the cotton thread and the cotton fabric generally shrink together and the quilt remains fairly smooth. When a cotton quilt sewn with polyester thread is washed, the cotton shrinks, the poly-ester thread does not, the quilt and seams can pucker. Some folks love that pucker, others do not.

Sewing Machine Needles. The following shows all the parts of a sewing machine needle by needle type: (source: pinterest.com)

The next chart shows that the European size and the American size are not the same number, but they are typically combined on your needle package. (source: SEWINGMACHINEFUN.COM)

When you hear someone speak of needle size, it is stated as 12 or 14 and so on. The needle package may show it as 80/12 and 90/14, featuring the European size first, then the American.

Matching the Thread Weight to the Sewing Machine Needle. The following chart shows you what type of needle and size of needle you need for specific types of fabric, and what size thread goes with the size of needle. The needle eye must be large enough to accommodate the size of the thread in a way that allows the thread to slide easily through the eye with the least amount of friction and no tangling.

When to Change Your Sewing Machine Needle.

Beginning in 2012, I began making quilts. Before quilting, I sewed garments, bags, toys, and did furniture and car upholstery. I learned how to make quilts and when to change needles from fellow quilters, experience, and doing research. These taught me to change my piecing needle each time I begin a new quilt project to ensure the needle was sharp enough to make my quilt top. Otherwise, if you have not sewed in a while and you cannot remember when you changed the needle, change the needle now. Currently, I have a small white board next to my sewing machine and I make a note when I last changed my needle and I note the size of the installed needle with a date. This simple step has saved me money by not changing a still sharp needle too soon.

If you notice your thread breaking, the needle makes a popping noise when piercing the fabric, or you have problems with your seam stitching, it is time to change your needle and to rethread the sewing machine. Before sewing on your project, test out the needle and thread with a scrap of fabric. If all is well, continue sewing your project.

I have also learned the hard way that I should remove my straight pins from my fabric before I run over them with the needle and thread. Running over a pin and having the needle hit the pin can break the sewing machine needle and/or the thread. The broken needle parts can ruin your fabric, hurt you, and possibly damage your sewing machine. It is recommended to change your needle if it hits a pin. The needle is most likely bent and will cause you problems sewing.

When you move from piecing to quilting, you will need to change from the size 12 piecing needle to a stronger needle to get through all the layers of the quilt sandwich. I recommend a size 14 for quilting or a larger size 16 if you are quilting through heavy thick layers or if your quilt top seams are especially bulky.

Some sewing machines sew at very high speeds like the Juki. The speed and friction causes the sewing machine needle shaft to become heated. If you sew at high speeds, you need a needle rated for high speed sewing. The heating caused by the high speed can weaken the shaft of the needle and can cause the needle to bend and break when it gets overly hot. If you are going to sew at high speeds, change to the appropriately rated needle.

That is it for this tidbit. I hope you enjoyed this journey with me. I learned a lot doing the research on this topic. Thank you again to Renee for this challenge. If you have an idea for a future tidbit, please let me know and I will be happy to research it and write it up. Blessings to you and your family. I plan to be back in February with another Educational tidbit. TTFN (tata for now).